MES Integration

Intro

In today's dynamic business environment, the seamless integration of Manufacturing Execution Systems (MES) with SAP is critical for optimizing operational efficiency and ensuring data accuracy across the enterprise.

Our dedicated expert teams at metalsXP stands out as the specialists in SAP integration for MES systems, committed to delivering out-of-the-box implementations that empower organizations to harness the full potential of their manufacturing processes.

You are selecting a partner dedicated to delivering SAP integration solutions that not only meet current needs but also provide a foundation for future growth.

Transform your manufacturing operations with confidence, knowing that your MES and SAP systems are seamlessly united by our expertise.

Integration as a service

We excel in providing MES integration services at two distinct levels, catering to the diverse needs of various industry sectors.

⛓️ Interfacing Excellence

- We design all the Interfaces as Asynchronous by nature, ensuring scalability of the overall solution

Our integration solutions excel in managing asynchronous data flows, ensuring efficient communication between MES and SAP systems. - We provide robust mechanisms for restarting interrupted processes (Objects locked, ...), minimizing disruptions and ensuring data integrity.

- We work closely with your business and IT experts, discussing and finding the best approach

- Our integrations are tightly controlled by UBC in SAP, aligning seamlessly with your existing SAP landscape. (optionally, but recommended)

Advantages when using UBC:

- centralized monitoring

- error handling

- alerting like email or ticket notifications

- message sequencing/queueing

- technology framework to use idocs, RFC but also up-to-date technologies like REST, ODATA, web service or proxy (XML) interfaces for SAP standard objects with no additional development (only customer extensions or custom objects as additional effort).

- it is not a replacement for standard technologies like ALE/DRF frameworks, it can be seen as an additional enabler for modern technologies/interfaces.

On a project basis, we offer consultany about the combination of S/4HANA data model with actual business requirements. To maximize the benefits of our MES integration solutions, we encourage organizations to engage with us early in their discussions. By including metalsXP from the outset, we believe that many common challenges can be preemptively addressed through our established best practices. Contact us to embark on a journey of MES integration that not only meets the technical intricacies of the SAP S/4HANA standard data model but also aligns seamlessly with your specific business needs. Together, we can unlock the full potential of your manufacturing processes.

MES integration of SAP S/4HANA standard data model

Our expertise extends to integrating crucial master data components, such as:

- Work Center details

- Bill of Material (BoM)

- Routing

- Production Version

- HR data like skills

- Material Master

- Class Characteristics

- Business Partner (customer, vendor)

- Cost Center

- ...

As well as essential transactional data encompassing:

- Quotation

- Sales Order

- Planned Order

- Production Order

- Purchase Order

- PM-Order

- Collective Order

- Batch

- ...

By weaving these elements together, we ensure a comprehensive integration that establishes a unified and scalable foundation for your manufacturing operations.

MES integration of our own Production Data Model

High configurable Industries using variable Products produced via multiple material states using complex order combination constructs can’t be integrated in SAP S/4HANA standard data model without very complex custom developments and/or enhancements.

Our dedicated expert teams at metalsXP have built the Production Data Model layer which is fully integrated and compliant with the SAP S/4HANA standard data model and processes.

💡 Key Features

- Unified Data Models

We pride ourselves on delivering standardized components, reducing implementation time and ensuring consistency. Our solutions are designed for easy extensibility, allowing organizations to adapt and scale their integrations effortlessly. Part of our solution are reusable components like Standard Specifications to handle recurring requirements easily and decouple from actual demands. Addressing recurring needs, we leverage standard objects and meticulous modeling techniques to ensure uniformity across Standards, Sales Orders, Production Orders, Technical Orders, and Costing Integration. - Easy Customer Extensibility

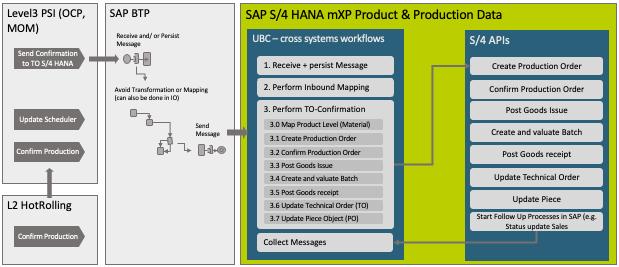

We prioritize flexibility by enabling easy customer extensibility at every step of the integration process. Our solutions therefore leverage Business Rule Framework Plus (BRF+) to facilitate intuitive rules modeling, empowering customers to tailor integrations to their unique requirements. - Controlled Cross-System Workflows

Our integrations usually are controlled by workflows enhanced with sophisticated monitoring technologies ensuring a harmonious flow of information.

Our layer and therefore the SAP system is the leading system when it comes to MES integration!

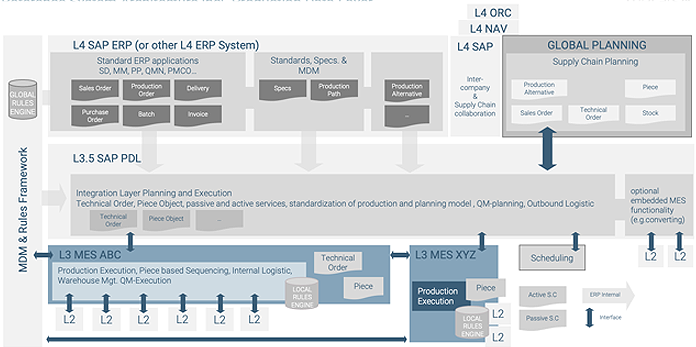

Reference System Architecture

Please find our reference system architecture which is based on our best practices.

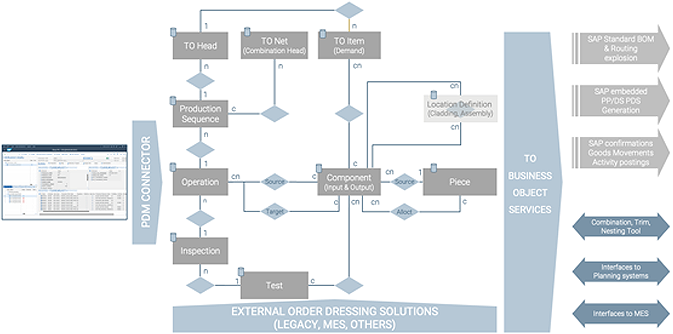

Production Data Model (Technical Order)

Please find an overview of our Production Data Model featuring the Technical Order component.

A Technical Order object is the object for communication between the SAP and MES system. It consists of an exact representation of Routing/BOM information dynamically calculated in SAP before. Also, all responses (movements, status updates, ...) of the MES system are persisted in the Technical Order object within SAP. Posting SAP messages like movements are handled within the Technical Order component.

Important to understand is that our layer and therefore the SAP system is responsible for controlling SAP internal necessities like wether to post, for example, a goods movement or not. Major benefits of decoupling these flow from the MES System are a way simplified error handling, reducing complexity and simplifying the architecture.